About Us

Our Mission

All too often, tin ceiling manufacturing companies sacrifice artistic harmony, unity of design, and production quality in the name of profits and competitive pricing. As lovers of the classic elegance of all tin ceilings, our foremost goal as both a manufacturer and distributer of tin ceiling tiles is and has always been to offer our customers the highest quality decorative ceiling and wall tiles at competitive prices.

These high standards have helped us to produce a wide variety of tin ceiling designs which incorporate artistic harmony, mechanical excellence, serviceability, and historical accuracy. The dies used in the manufacture of our metal ceiling tiles are of the highest quality, and we are unshakably confident in our products’ superiority. Furthermore, we go the extra step to take care of our home, producing our quality tiles with green manufacturing practices right here in the United States.

As a potential customer, we solicit your careful inspection of our products. Whether you are a homeowner seeking to bring style and elegance into your living room or the owner of a new or established business hoping to create a classic and confident aesthetic in your commercial establishment, we are sure that you will not be disappointed by our offerings.

Please do not hesitate to contact us with any questions you may have regarding our products or their installation. With your help, we hope to one day ensure that authentic metal ceilings become the number one choice for quality ceiling design.

Thank you,

The Tin Ceiling Xpress.com Team

>> Go to Customer Testimonials

>> Contact Us for More Information

>> Browse Our Catalog

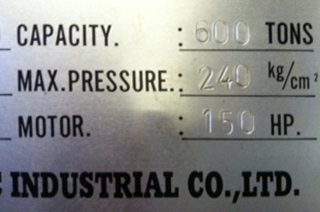

"Size Matters"

Our Mammoth 600 ton Hydraulic Press allows us to produce the highest quality products in the industry. Please take advantage of our quality guarantee offer before ordering from any of our on-line competitors

Merlin operation press #1 our mammoth Niagara stamping press

Tin Ceiling Presses

Tin Ceiling Bliss Power Press #2

"The Granddady of them all"

Tin Ceiling Press #3

Press plate from Bliss Power Press #2

Made in Brooklyn - the birthplace of Tin Ceilings.

Tin Ceiling Inventory

Thousands of Tin Ceiling Tiles in stock and ready for immediate shipment from our warehouse location.

Oscar Jesus & Marcus- The Men of shipping & receiving

Tin Ceiling Xpress Powder Coating Process

A View of Our Powder Coating Spray Booth & Curing Oven

Powder Coating

Powder coating is a process of applying dry paint to a tile/cornice.

The powdered paint is applied by being electrostatically charged and sprayed onto the tile/cornice.

The tiles/cornices are then baked in an oven to allow the paint to form a smooth complete surface.

Shanko has its own state-of-the-art powder coating facility onsite! This process uses static electricity to adhere powdered pigment to the tiles, which are then cured in our ovens. All tiles are available in a range of RAL colors, and can be color-matched to Benjamin Moore or Sherwin Williams palette. Cornices, Drop-grids and accessories can be powder coated to match your tiles.